In first part we discussed about the detail of circuit, back EMF and Mosfet protection; and in second part we covered the display and menu, in this third and last part we will build and test our project.

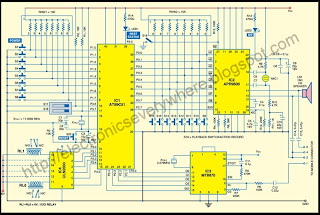

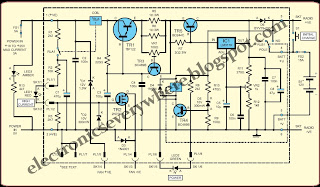

The DC Motor Speed Controller is built on two PC boards: a main board, and a display board. These are joined together via a 12-way flat ribbon cable, which plugs into a pin header on the main board.

The main board can be assembled first – see Fig.9. Start by checking the PC board for hairline cracks and for any visible shorts across the copper tracks, especially between the ground plane and any adjacent tracks. In addition, check the hole sizes for the larger hardware items by test fitting these parts into position.

Making a link

That done, begin by installing the 17 wire links. These must go in first, since some of them run underneath some components.

To straighten the link wire, first clamp one end in a vice, then stretch it slightly by pulling on the other end with a pair of pliers. It’s then just a matter of cutting the links to length and bending their leads down through 90° to match the holes in the PC board.

The DC Motor Speed Controller is built on two PC boards: a main board, and a display board. These are joined together via a 12-way flat ribbon cable, which plugs into a pin header on the main board.

The main board can be assembled first – see Fig.9. Start by checking the PC board for hairline cracks and for any visible shorts across the copper tracks, especially between the ground plane and any adjacent tracks. In addition, check the hole sizes for the larger hardware items by test fitting these parts into position.

Making a link

That done, begin by installing the 17 wire links. These must go in first, since some of them run underneath some components.

To straighten the link wire, first clamp one end in a vice, then stretch it slightly by pulling on the other end with a pair of pliers. It’s then just a matter of cutting the links to length and bending their leads down through 90° to match the holes in the PC board.